PMM | Intermittent motion horizontal cartoner

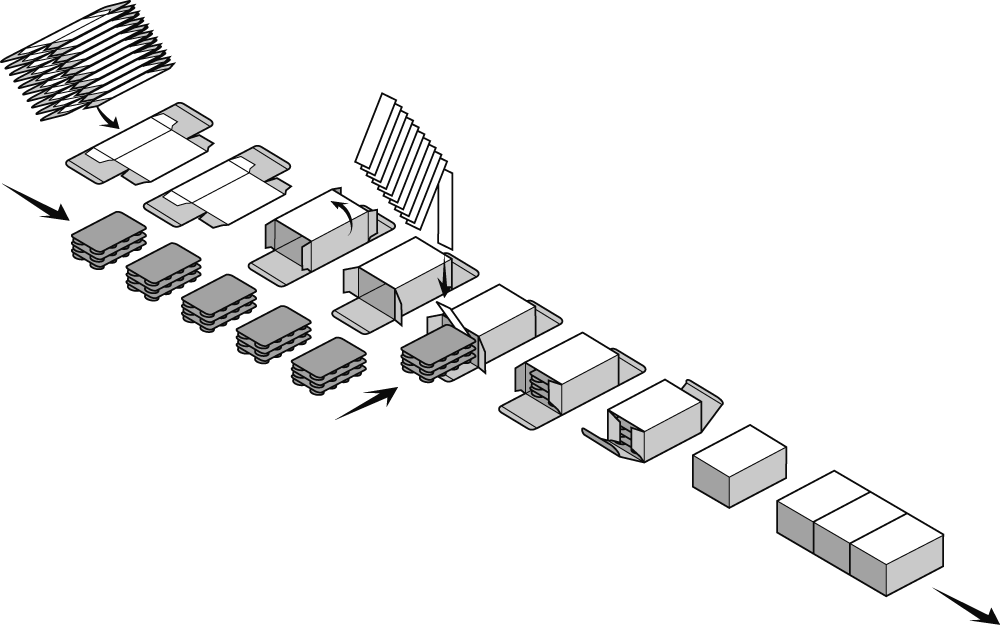

Machine working flow

Description

What has allowed the PMM intermittent motion horizontal cartoner to become a significant reference in the packaging sector owes to having maintained the technical solutions which have made CAM cartoners the choice of thousands of end users worldwide, for their reliability and flexibility, without overlooking project updating in requirements.

Carton erection, carried-out by means of an articulated twin blade inserted into the carton ensuring positive pre-breaking, allows low grammage board to be used even when handling square-section formats or carton with glueing and creasing imperfections. Perfect product introduction (even for products with irregular shape/dimensions) is guaranteed by the insertion of the moveable mouthpiece inside the carton, avoiding any uncontrolled passage of product from bucket to carton. Products are also prevented from straying out of the carton by the action of the spring loaded guides which automatically close during the return stroke of the pusher. The use of closed profile cams with surface hardening treatment, guarantees the reliability of all positive driven movements during the course of time.

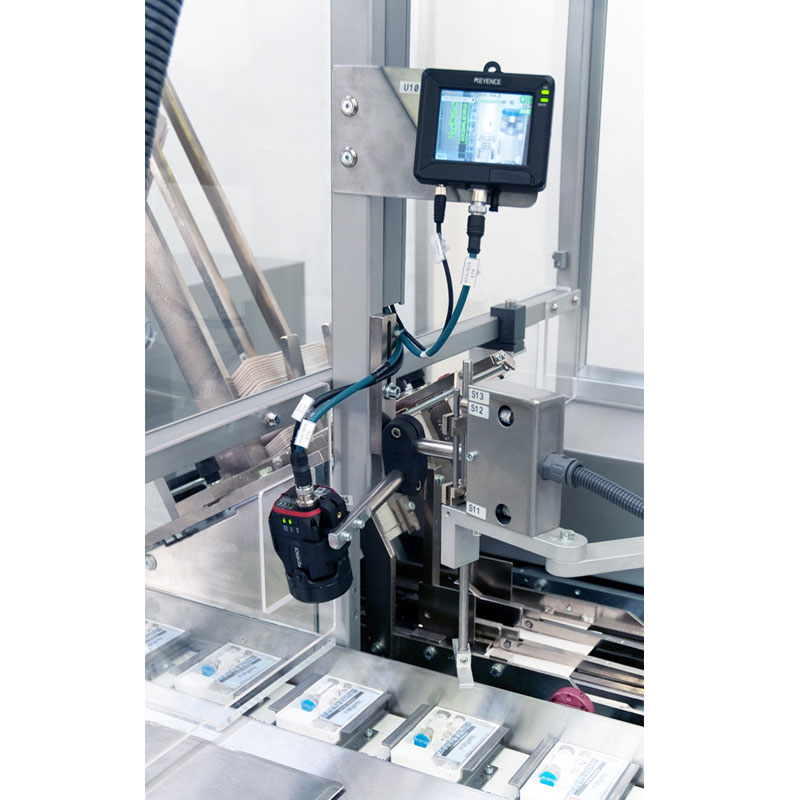

Particular attention has been given to machine cleaning below the carton transport area, where possible product or packaging material residue is conveyed to easily accessible collection areas. ThePMM cartoner can be equipped with a complete range of product feeding systems and additional units, such as: coders, leaflet and booklet feeders, detection and reject devices, etc.. As on all CAMmachinery, the PMM is also equipped with the Mechanical Memory® system, transforming complete size change-over into a series of rapid and pre-set operations, which can be carried-out by unskilled personnel allowing production to be resumed immediately without the need for fine-tuning adjustments.

Packed products

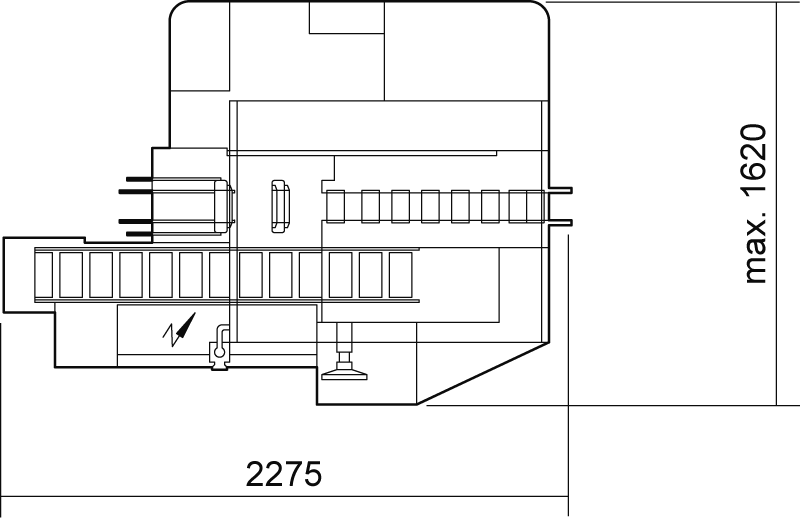

Machine layout

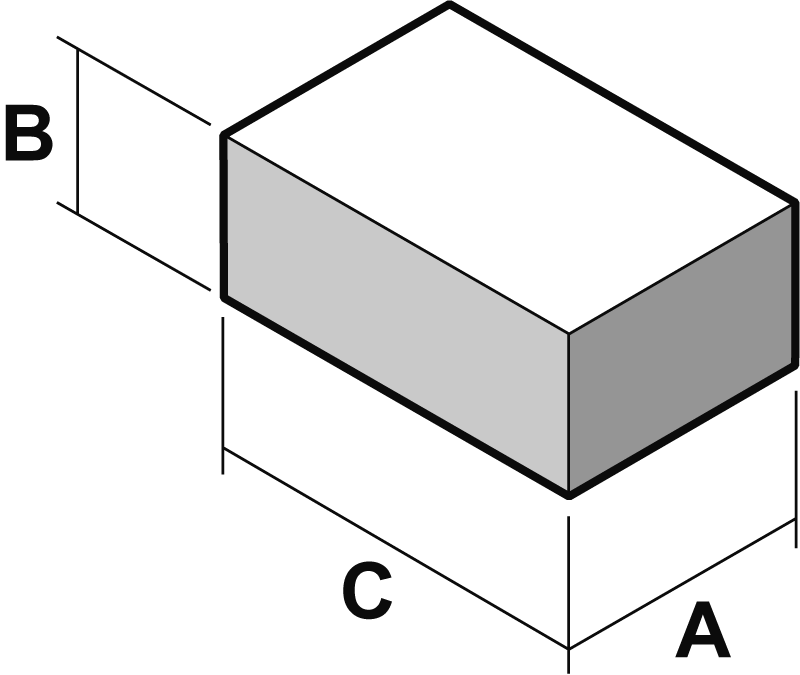

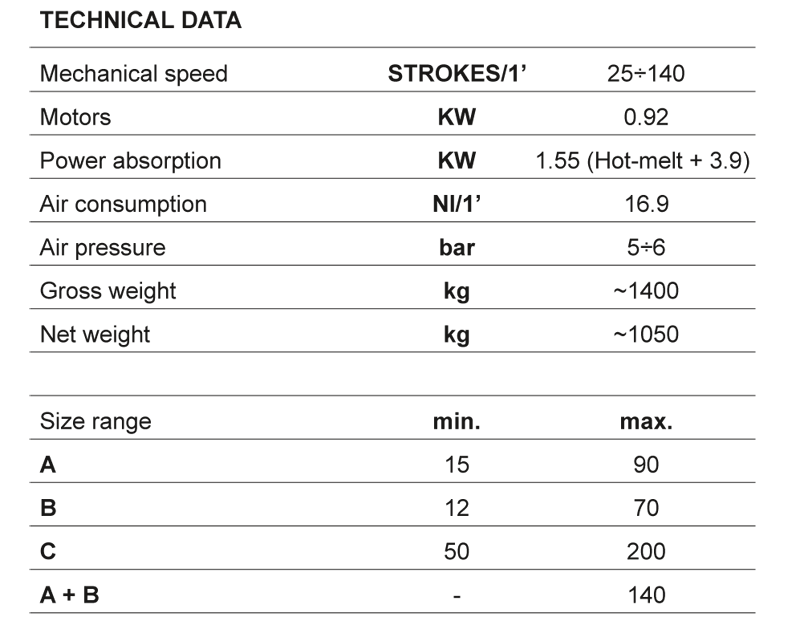

Size range