MT32 | Testing machine for spray cans

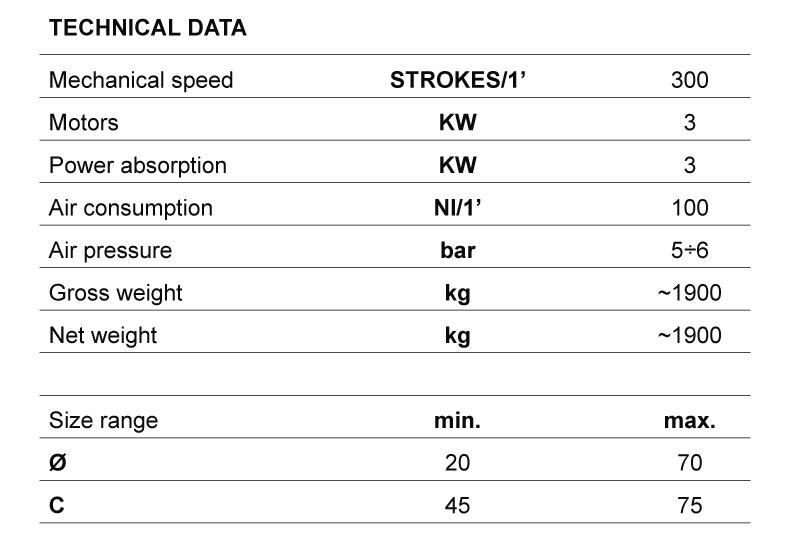

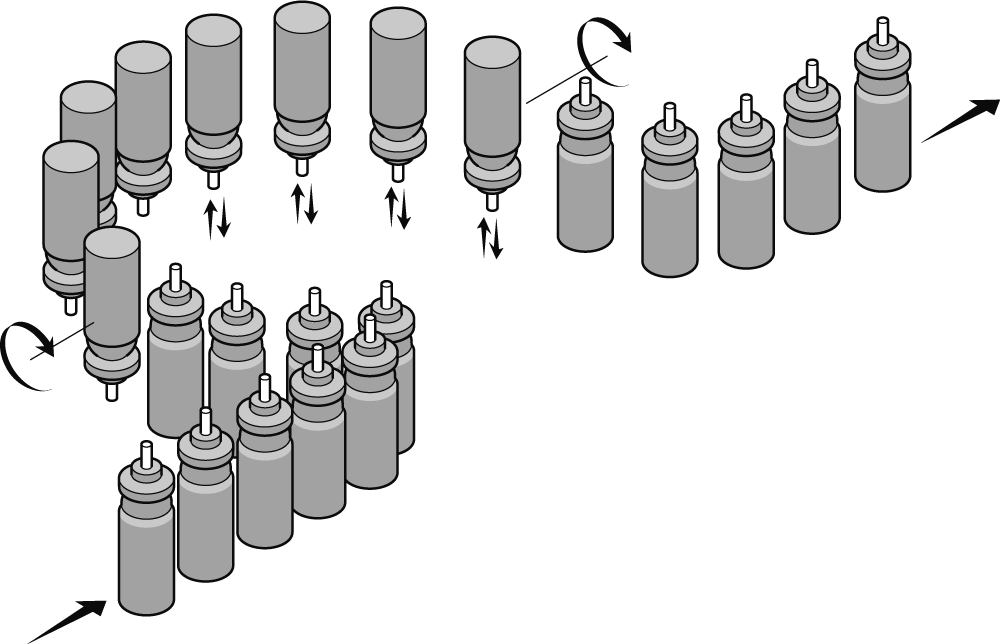

Machine working flow

Description

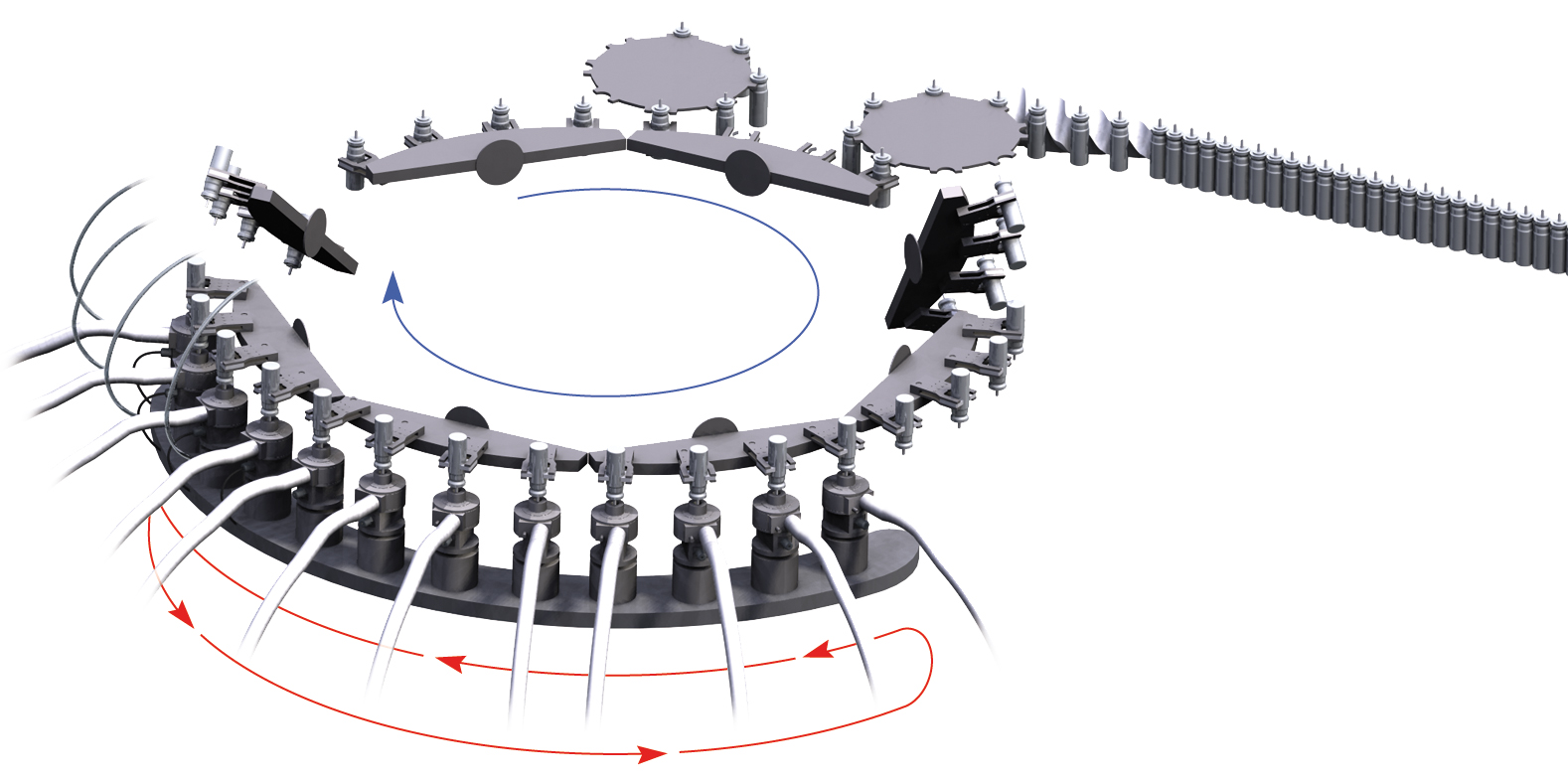

The MT32 is the new CAM machine designed to check the correct operation of the single dose valve in aerosol cans for pharmaceutical use. This patented control system is based on piezoceramic sensors, where the electrical signal generated is amplified, filtered and measured making it possible to detect if products are compliant or not, according to two assigned parameters.

The piezoceramic sensor generates an electrical signal proportional to the product flow pressure acting upon the sensor itself each application. The electrical signal is represented by a flow on a diagram, where “Y” axis is the intensity of pressure and “X” axis is the duration of delivery.

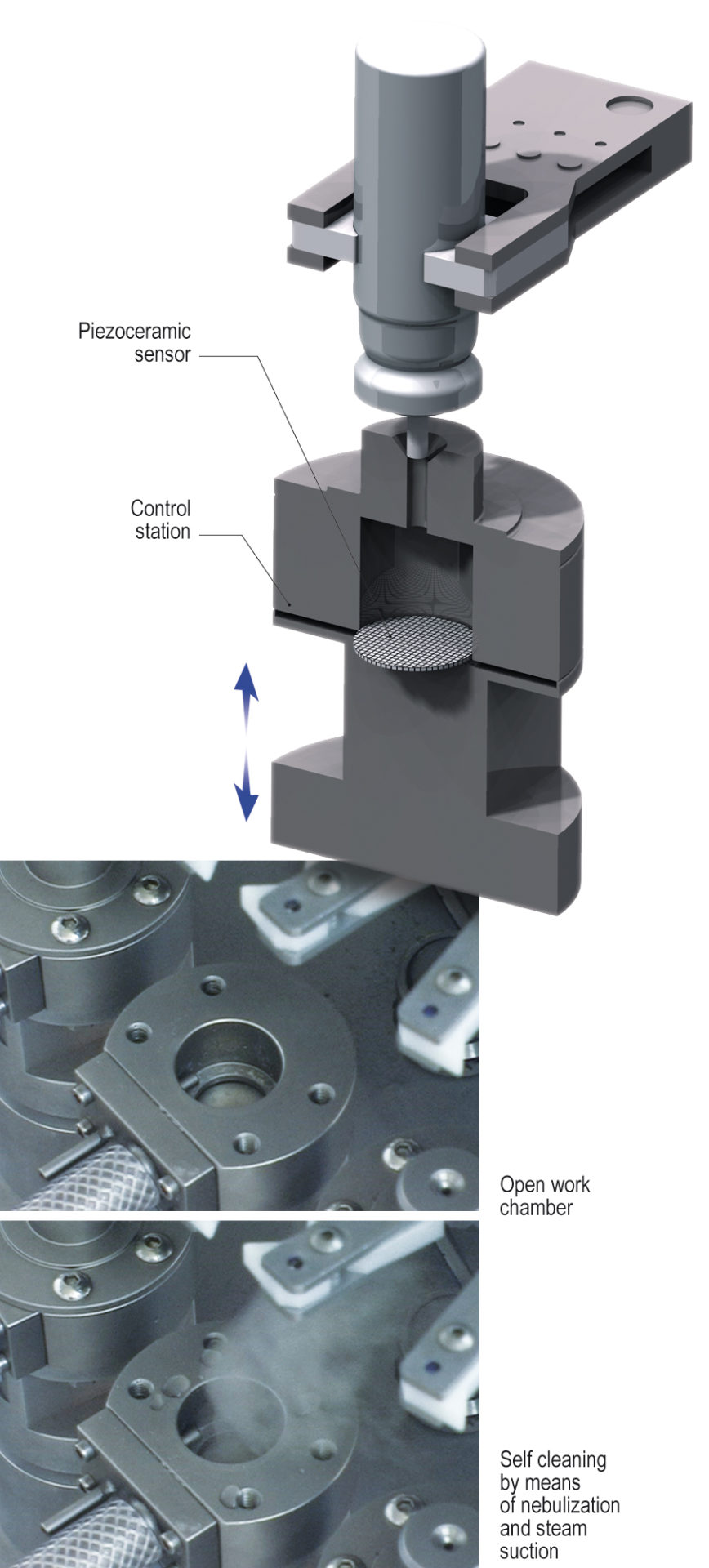

One of the features of MT32 is the self-clean function necessary to remove the product residue and to re-establish the initial conditions. The frequency of the cleaning cycles is variable and can be set subject to the type of product. The automatic self-cleaning function will prevent any operator/product contact. This function is a fundamental requirement in the pharmaceutical industry where toxic products, such as asthma drugs, are dealt with.

The cleaning cycle is automatically performed by the machine without stopping. During the self-cleaning phase, the machine will automatically empty of all products and prevent the entry of other products by means of a contrast piece, located in the scroll on machine infeed. In event of powder-base products, a solvent will be introduced inside the control chamber in order to facilitate product atomization. The piezoceramic sensor resonates atomizing the solution which is then eliminated by the aspiration system.

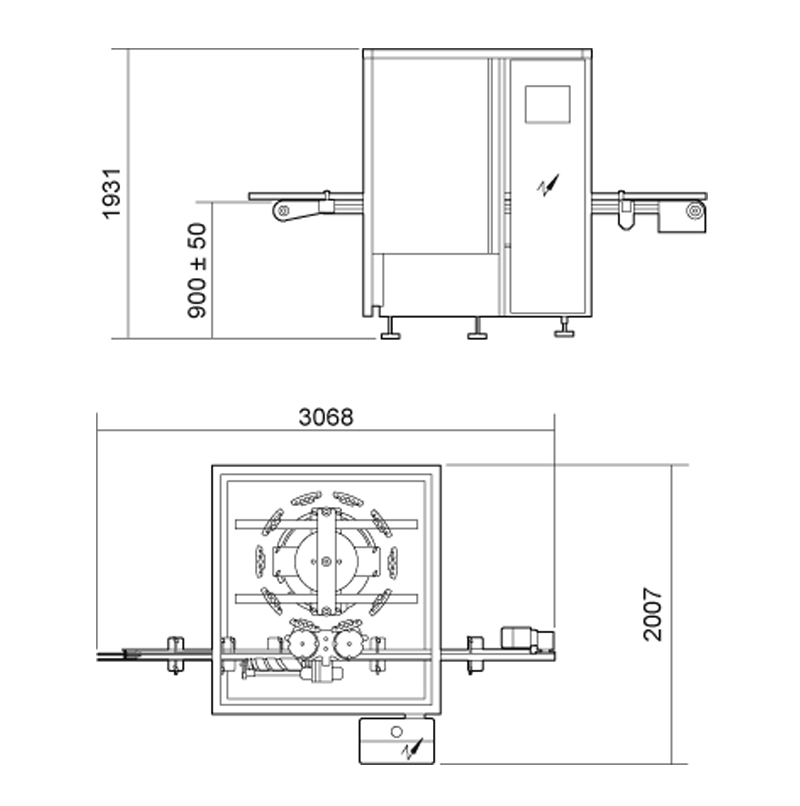

Machine layout

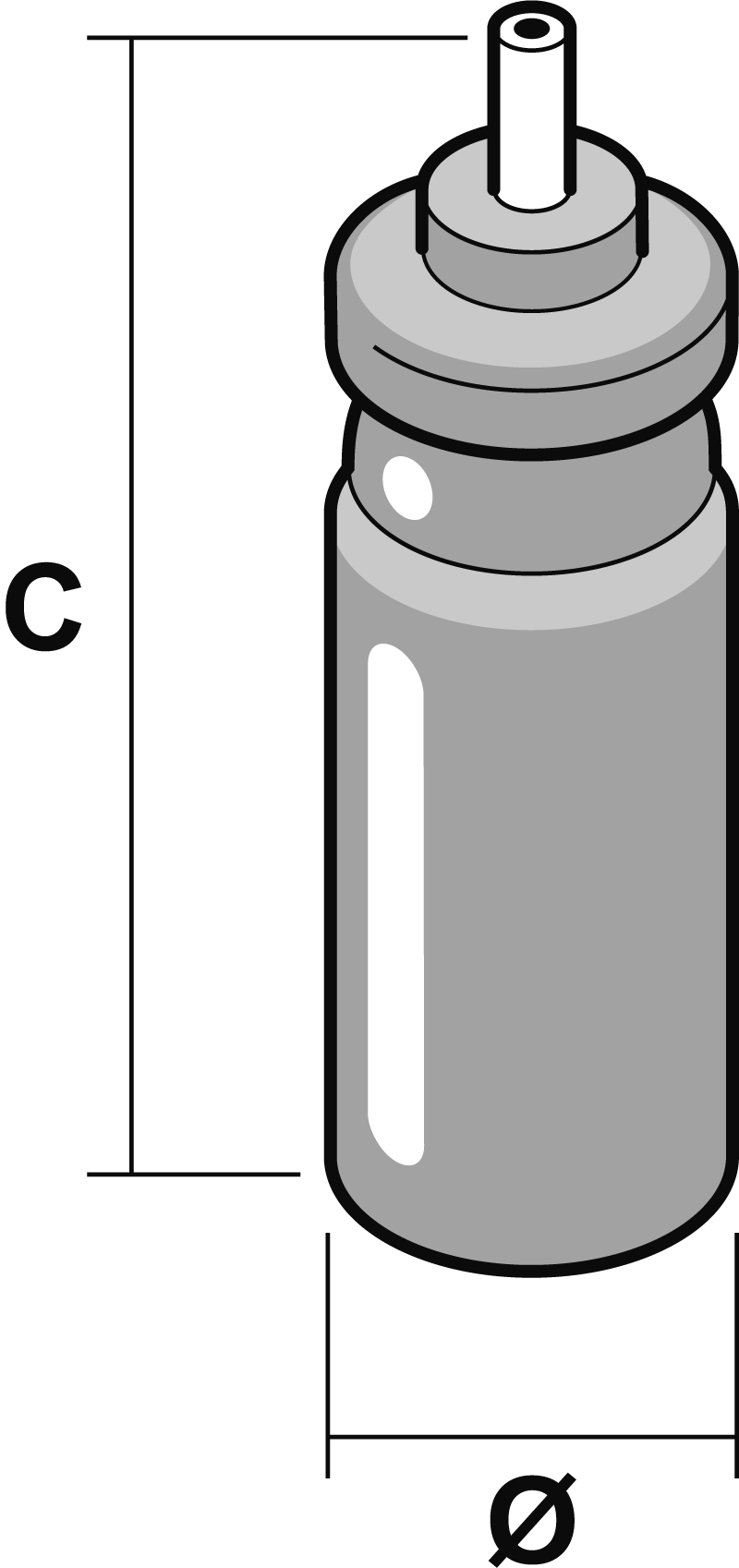

Size range