ASB38 | Bundler with stretch-banding or shrink-wrapping

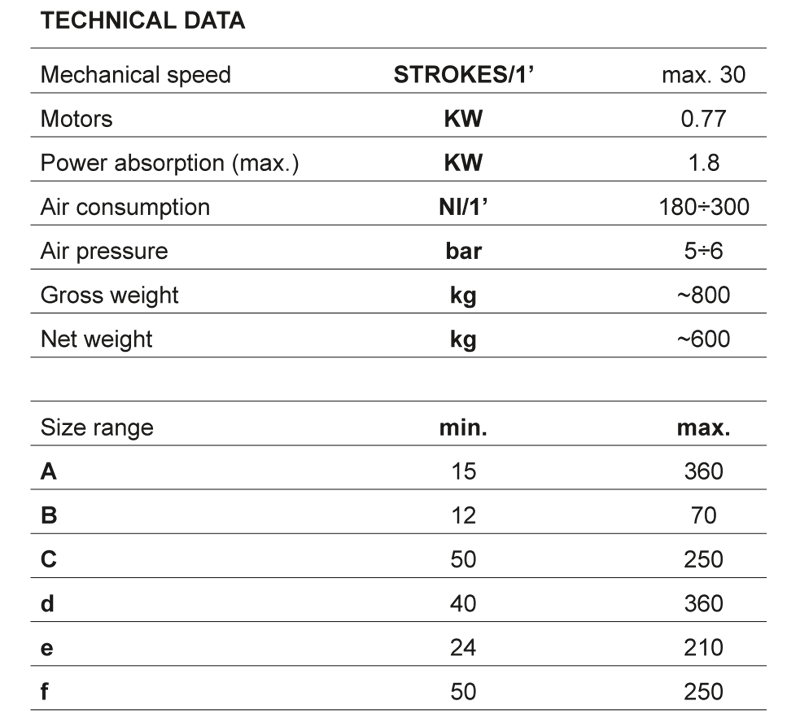

Machine working flow

Description

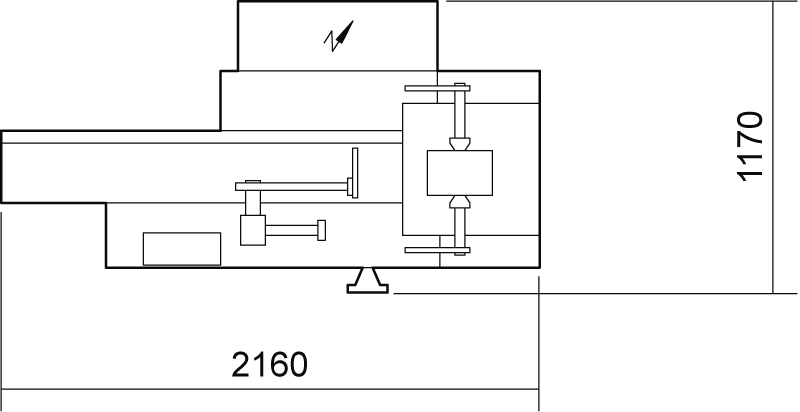

The CAM automatic bundler model ASB38 is one of the simplest and most compact machines available on the market. It can solve any problem relevant to collation and bundling of cartons, bottles, trays, and various products in any arrangement.

Designed on the basis of the CAM well-proven engineering standards, the ASB38 machine gives to the users high level performances and remarkable reliability, thanks to the following technical features:

• The use of a single reel of wrapping material allows a better usage of it and a real reduction in changeover times

• The electromechanical stretching system allows a constant band tension independent of the reel diameter

• The single sealing position, accurately repeated on the bundle, considerably improves the package appearance

• The sealing obtained by means of a sealing bar in conjunction with a film brake unit, guarantees an excellent uniform seal

With the in-line infeed version, products are fed onto a conveyor belt, collated with pneumatic system and transferred with mechanical movement in the wrapping area. As it travels forward, the collation drags the film held by a system of rollers which enable pre-stretching of wrapping material.

In the successive phase a vertical movement completes film wrapping and stretching and brings it to the sealing/cut area. This combination of operations completes the working cycle of the machine.

This machine can be equipped with various collation systems, depending on the kind of packing required. It is also possible to have different versions to handle special products, such as blisters.

Usually ASB38 machine uses stretchable film, however it can also use shrinkable films to carry out shrinkable “sleeve” wrapping. In this case it can be completed with the heat-shrinking tunnel TRM38.

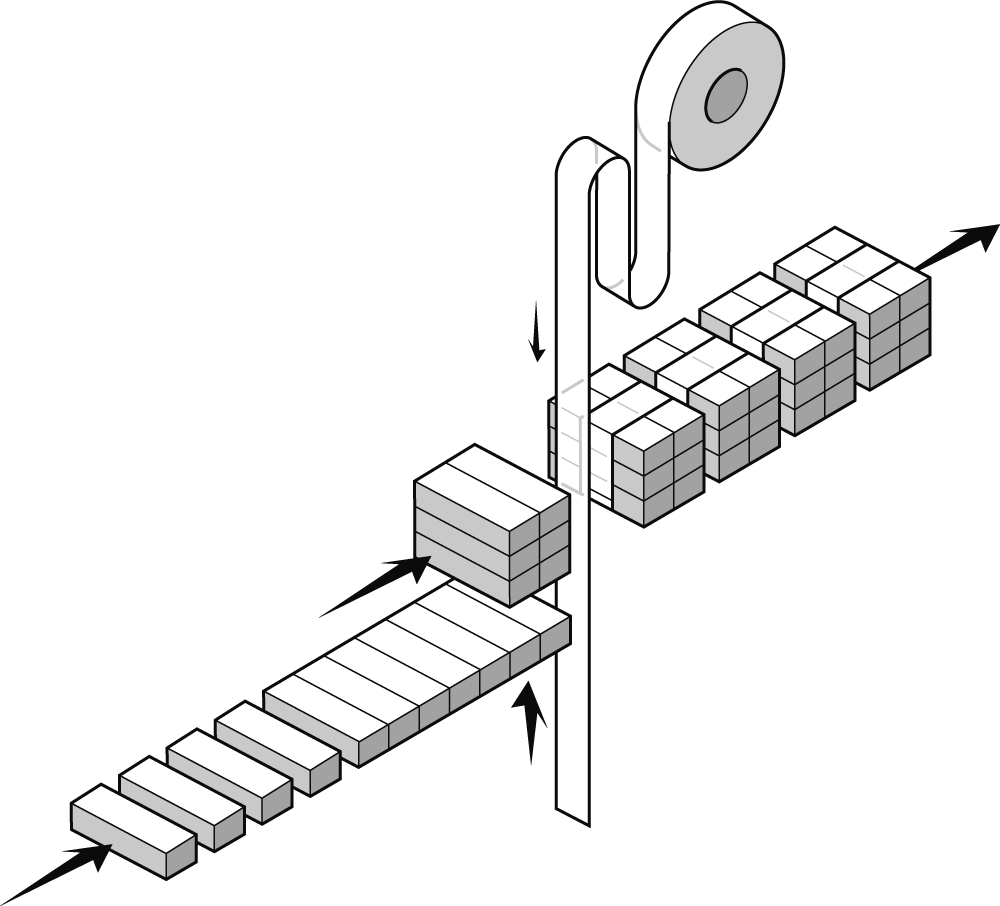

Machine layout

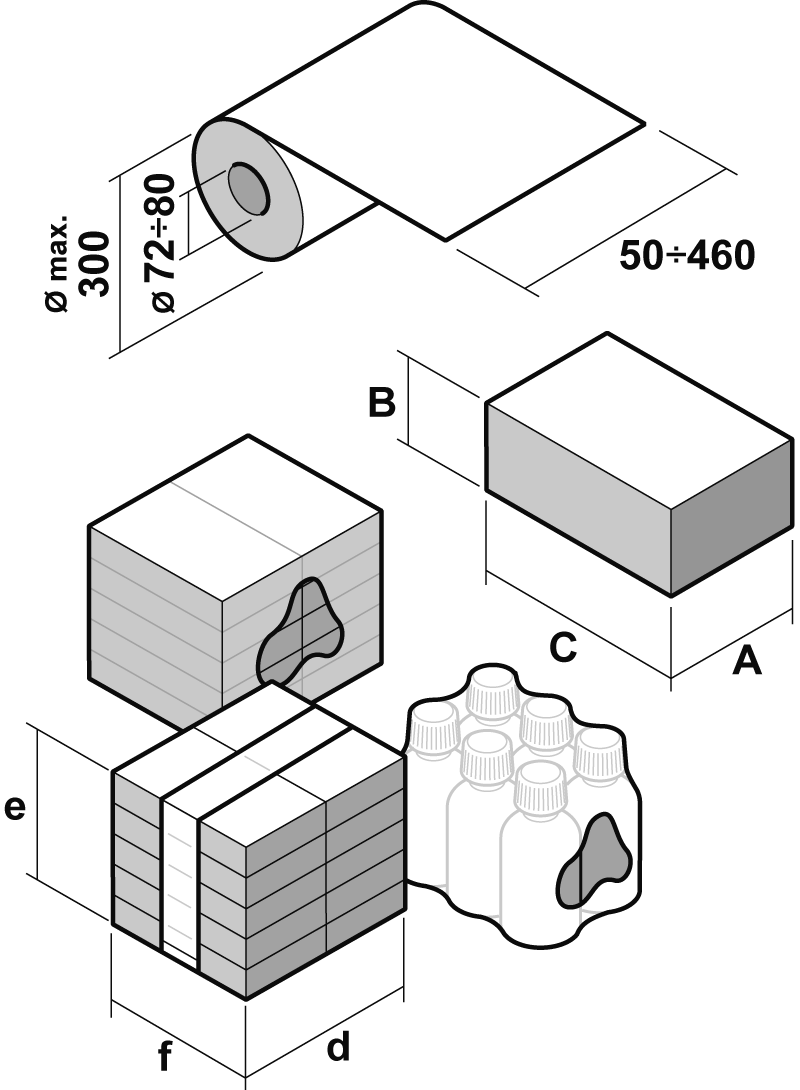

Size range