MS | Rotary continuous motion bottle cleaning machine with blowing/suction system

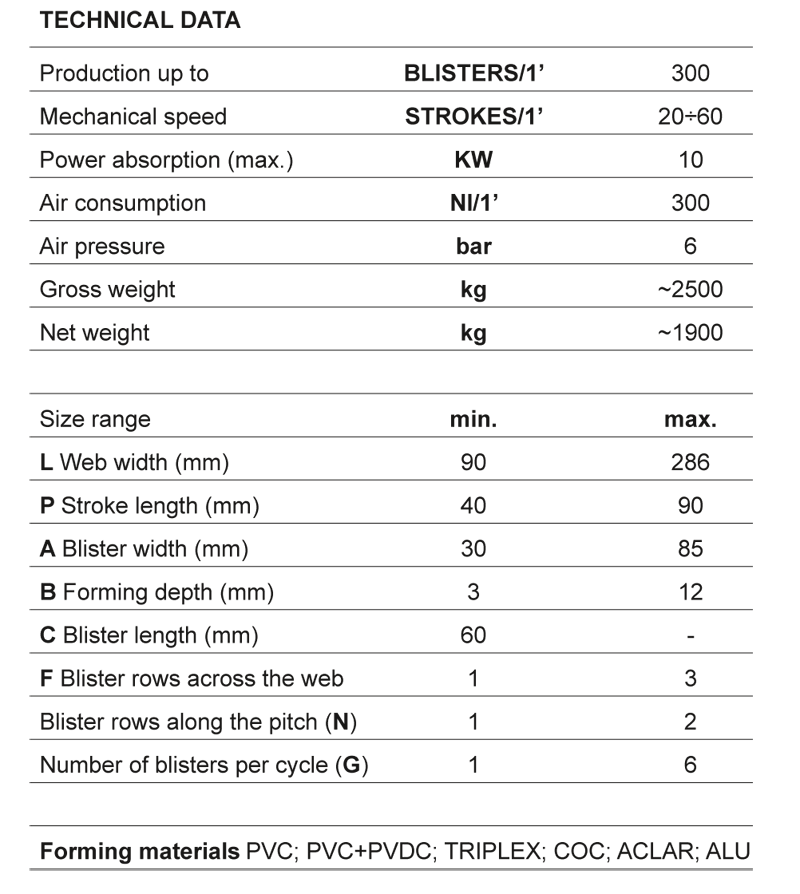

Machine working flow

Description

Modern packaging systems for glass or plastic containers allow, in most cases (owing to the cleaning standard of the product contained) to eliminate large, complex and difficult to manage washing machines from packaging lines; at the same time this makes the use of blowing machines necessary to eliminate particles or impurities left by external packaging materials from inside the bottles.

For connection upstream to their filling systems, CAM proposes a complete range of blowing machines,MS16, MS20, MS30 which, thanks to the possibility of being able to accomodate different numbers of blowing nozzles, can reach production speeds up to 30.000 bottles/hour.

Tests, carried-out by end users of these machines for internal bottle residue, demonstrate the high standard of cleaning achieved by CAM blowing machinery. Bottles, synchronized by a timing scroll, are picked-up by a series of mechanical grippers, assembled onto a continuous motion rotary turret, which, by turning them upside-down, allows the blowing nozzles to be inserted into the bottles from below, with the consequent centering of the suction devices onto the bottle necks. Each nozzle releases air at high pressure (4 atms. with PALL filtering at 0.2 microns) which removes every particle from the internal sides of the bottle allowing, along with the simultaneous action of the suction devices, immediate elimination to be achieved. The possibility to install an air deionising system guarantees the removal of any kind of particle sticking to the inside of plastic bottles caused by electrostatic charges.

The extremely compact dimensions, rationality and simple construction allow inspection and cleaning to be carried-out with ease.

Packed products

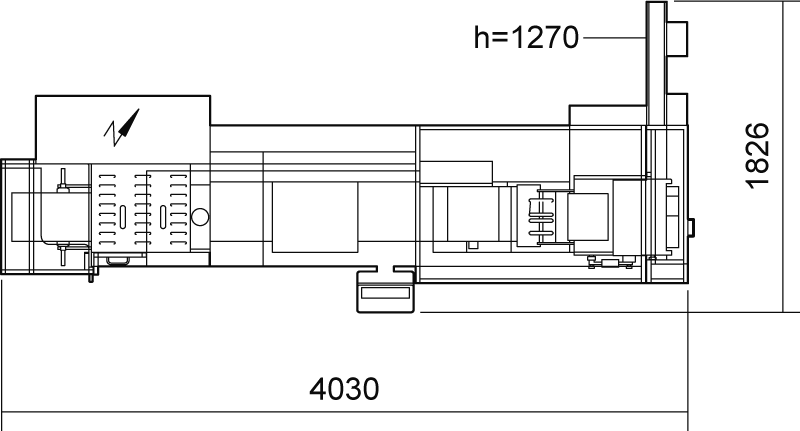

Machine layout

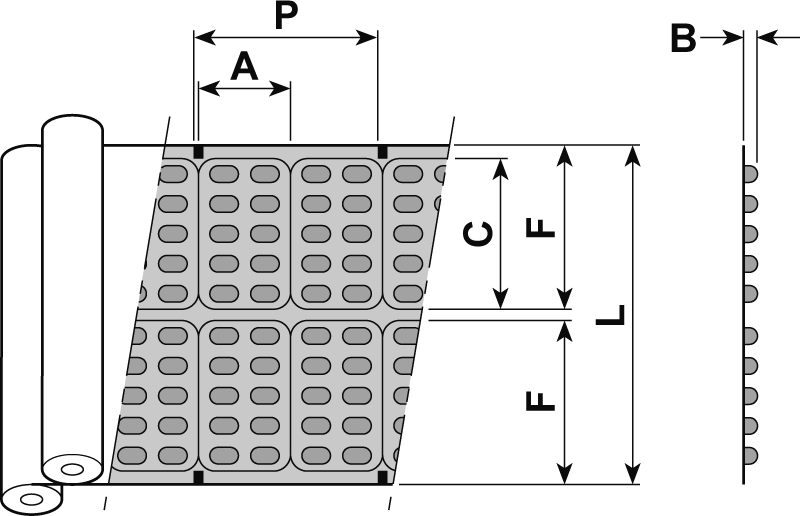

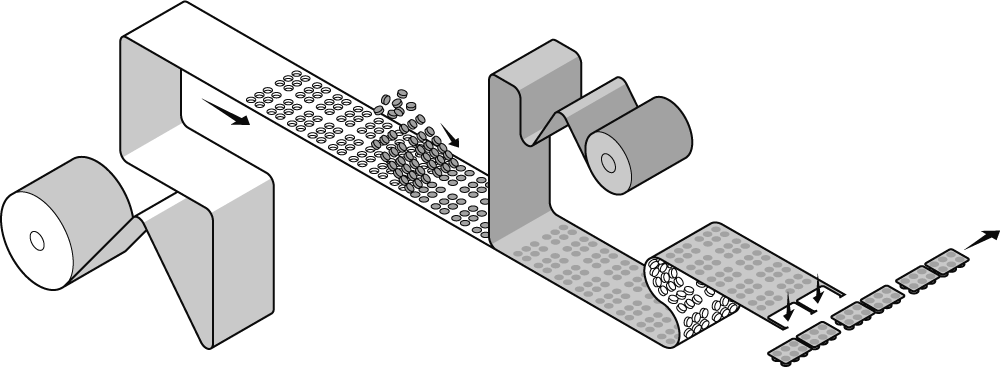

Size range